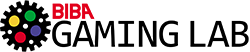

Practical lab exercises and haptic games are often used to create understanding and awareness of how technologies can support the quality of warehouse operations. However, not all students have access to a suitable physical lab or game environment. To make this possible, a team in gaming lab BIBA is working on a mixed reality game, a mode of free form that emphasizes freedom of movement and offers the player a lot of flexibility and ingenuity in completing tasks and coming up with solutions to the objectives of learning(focusing mainly on exploring benefits and limitations of using sensors in warehouse operations) with a combination of Augmented Reality and physical tools. The purpose for playing this is to promote the importance of using sensors to increase the efficiency of logistics operations.

Keywords

Sensor, Actuators, Augmented Reality, Mixed Reality, Warehouse Operations, Risks, Production Logistics.

Target Group

This MR game environment is designed to support everyone who wants to understand better how different sensors and actuators can be used in a warehouse environment.It is designed as a sandbox game and can therefore be used both for those with basic knowledge and practical skills as well as those with advanced skills in ICT supported warehouse operations.

Learning Objectives

- Know the function and specifications of different types of sensors and actuators

- Understand how sensors and actuators can support data-driven logistics

- Understand the opportunities and limitations of the implemented technology in a warehouse operation

- Apply methods to analyze how the technology affects warehouse operations

- Evaluate how the different technologies can support the decision-making process in warehouse operations

- Create an understanding of how the knowledge gained can be transferred to one’s own working environment (only for VET and LLL settings)

In the Process of Investigating and Selecting Sensors

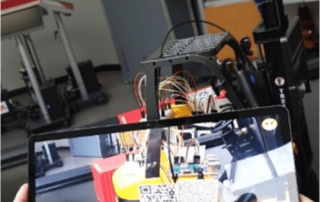

Player control forklift with controllers on tablet and when scanning QR codes on forklift it pop up AR interactions providing information about sensors used. This would be helpful for technical learning in logistic operations and IoT in learning environment to have more practical knowledge about different sensors in an immersive manner.

In Decision Making Operations – Instructional

Player controlling forklift with tablet and with sensors information application giving player instructional information in order to avoid collisions and hit by any obstacle. Three Ultrasonic sensors are mainly used for this purpose, which are measuring distance of forklift with any coming obstacles.

PBL and Sensor Selection

List of sensors used for the Forklift:

- Ultrasonic sensors (used)(HC-SR04)

- RFID sensor (used)(RC-522)

- Camera (used)

- Time of flight sensors (used)(VL53IOX)

- Gyroscope (used)(GY-521)

- Proximity sensors

- Pressure sensors

- Vibration sensors

- Accelerometer sensors.

- Touch sensors

Actuator used:

- L298 H-Bridge

Data-Driven Warehouse Logistics Concepts

Due to changes in the working requirements for people working within production and logistics operations, there is a need for training and educational offers that prepare current and future employees for these requirements. With this prototype, there would be an opportunity to try out how different technologies (in this case, sensors, actuators, and augmented reality) can support operations and provide a safer working environment.

In a lab (remote or physically on-site) or a test bed, gamification approaches can be applied to both the virtual and the physical environment. A part of the purpose of the lab is that you as a student can experiment with different settings. In some cases, you will do that by changing the sensor, while we also foresee that you will deal with the manipulation of data from the physical environment in the virtual (unity model) to support the planning process. The intention is to foster a deeper understanding of how the accuracy of a sensor may be affected. For this purpose, in the virtual part (i.e. the DT), we only map the relevant processes, with the data either imported directly from the physical demo area or reused from a database.

We have integrated different kinds of mechanics into the decision-making process of a simulation. This includes information on time spent on movement, on how the vehicle has moved, the quality of the service delivered, the selection of different sensors or actuators, etc. The mechanics implemented depend on the specific aim of our investigation, so you may use it in different ways, depending on the problem in question. For a focus on the operating processes, other KPIs (like mistakes, bumps, etc.) would have been of more interest than mechanics. To realize the current prototype, we created the digital twin of a warehouse in which IoT technologies are used.

Please access a comprehensive online learning chapter “Data-Driven Warehouse Logistics Concepts” to have more detailed insights.